TAG3’s client base includes startups at all funding stages and large corporations. We are a one-stop-shop for all things Medtech.

Our services include:

- Skunkworks

- Clinical need definition

- Concept generation

- IP Development

- Industrial Design

- Product Design

- Finite Element Analysis

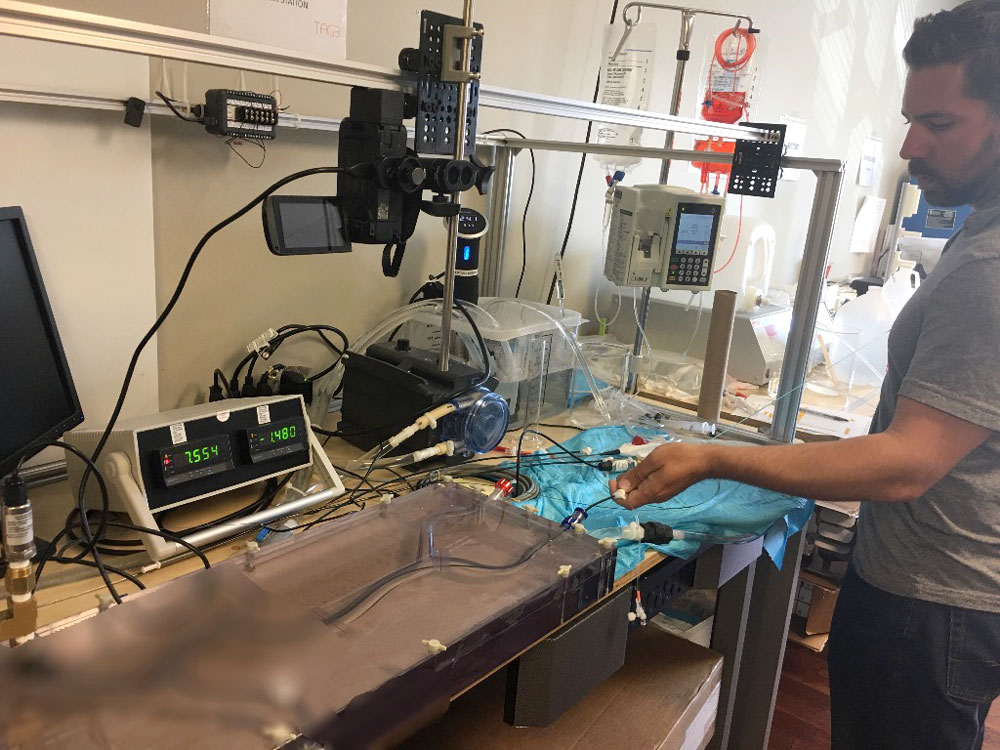

- Prototyping

- Product Development

- Regulatory Submissions

- Budget Development

- Fundraising

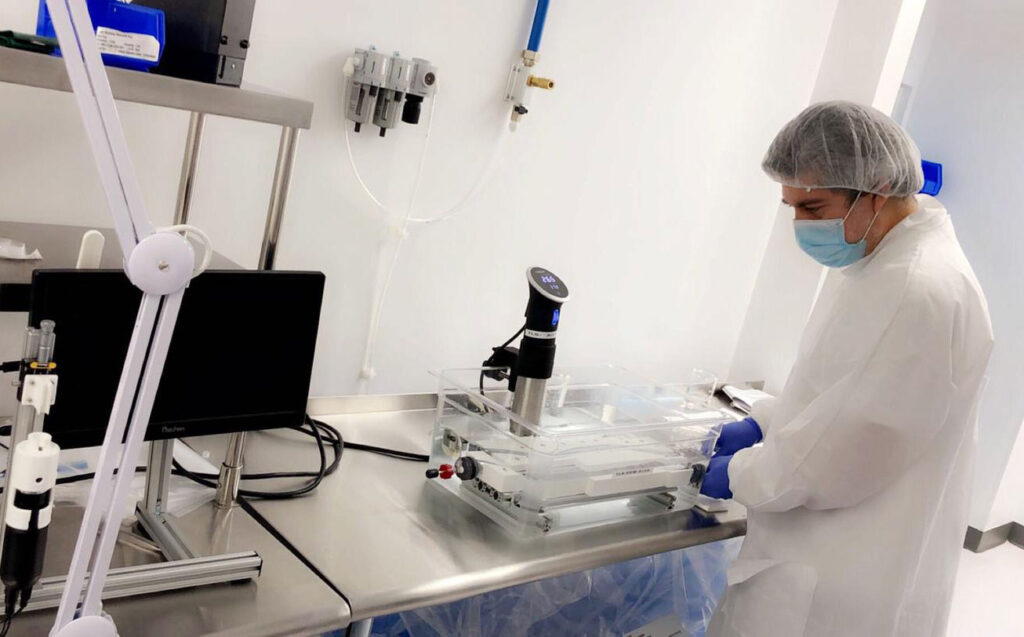

- Manufacturing Process Development

- Manufacturing Operations

- Quality Remediation

- Regulatory Remediation

- Product Function Animations